what is acc?

Autoclaved aerated concrete (AAC) is a proven ultralightweight concrete construction technology used globally to drive increased performance and resilience while lowering the total lifecycle costs of modern built infrastructure.

WHY TEXAS BUILDING OWNERS CHOOSE AAC

Autoclaved aerated concrete (AAC) is a proven ultralightweight concrete construction technology used globally to drive increased performance and resilience while lowering the total lifecycle costs of modern built infrastructure.

PERFORMANCE

Energy efficient, quieter, healthier, and more comfortable building spaces

PERFORMANCE

Energy efficient, quieter, healthier, and more comfortable building spaces

FIRE SAFETY

Non-combustible material offering up to 4-hour fire-rated wall, floor, and roof assemblies

RESILIENCE

Comprehensive protection from mold, mildew, rot, pests, and storms

LOW COST OF OWNERSHIP

Competitive cost of construction plus reduced long-term maintenance, repair, energy, and insurance costs

PHYSICAL PROPERTIES OF AAC

AAC is a lightweight, precast concrete material made from cement, lime, sand, water, and aluminum powder that is steam-cured under pressure to create a strong, fire-resistant, and insulating building product.

HOW AAC IS MANUFACTURED?

The manufacturing of AAC is based on a controlled chemical reaction in the concrete slurry that creates permanent air voids in the material, which gives these products their low weight, insulating performance, and non-combustible physical properties.

The steps of production are:

Raw material preparation: Cement, lime, sand (or fly ash), water, and aluminum powder are precisely measured and mixed.

Mixing and aeration: Aluminum reacts with the alkaline slurry, creating millions of microscopic air bubbles.

Casting and pre-curing: The expanding mix is poured into molds and allowed to partially set.

Cutting: The semi-hardened “cake” is wire-cut into blocks, panels, or lintels.

Autoclaving: Products are steam-cured under high pressure and temperature to gain strength and stability.

Finishing and packaging: Units are inspected, packaged, and prepared for shipment.

WHERE AAC WORKS BEST

Autoclaved aerated concrete building systems have been used in multiple applications for commercial, industrial, and residential projects in the United States since the 1990s.

AAC BUILDING SYSTEMS

Autoclaved aerated concrete products are categorized into three classes of block and steel-reinforced panels.

-

Thin-Reinforced Panels

Lightweight and resilient AAC panels with single internal steel reinforcement in 2- to 3-inch thicknesses and lengths up to 8 feet.

✓ Power Panel

✓ Power Floor -

Large-Format Panels

Lightweight AAC panels with double internal steel reinforcement in thicknesses of 4-12 inches and lengths up to six meters (19’-8”).

✓ Wall Panel

✓ Floor & Roof Panel

✓ Vertical Load-bearing Wall Panel

✓ Fence & Sound Wall -

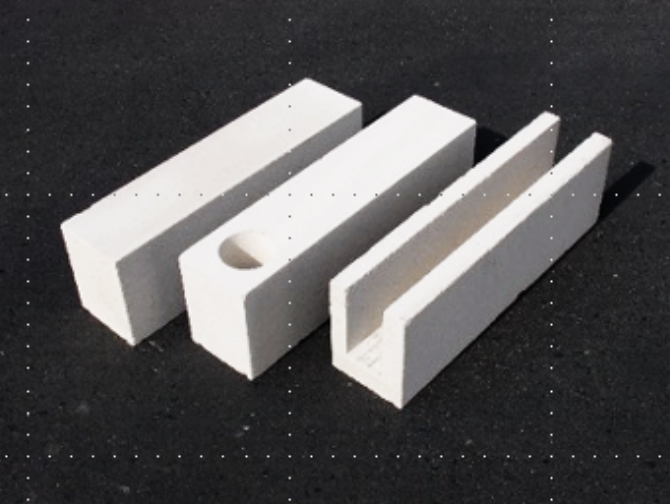

Masonry Blocks

Insulated and fire-resistant AAC blocks in thicknesses of 4-12 inches for use in reinforced and confined masonry designs.

✓ Masonry

WHERE AAC WORKS BEST

Autoclaved aerated concrete building systems have been used in multiple applications for commercial, industrial, and residential projects in the United States since the 1990s.

PROJECT SUCCESS STARTS HERE

Get started with a free project evaluation — see how Modular solutions can improve your design outcomes, speed up construction, and maximize project value.